- #Pro ii simulation manual manual#

- #Pro ii simulation manual registration#

- #Pro ii simulation manual pro#

- #Pro ii simulation manual software#

- #Pro ii simulation manual download#

After you have converged the column, come back and adjust it. At this point, it is also possible to avoid putting the valve into flowsheet and add it later when the column has converge and pressure is known. We do not know exactly what this is at this point, but we will make an assumption and define it as slightly higher than expected to be on a safe side for the calculation purposes. The pressure at the exit of the feed valve must be equal to the pressure on the feed tray. So, make the specification for both pumps in accordance.

If you do not have any specific data or requirements, it is appropriate to make the assumptions that both pumps will generate a pressure difference of 5 bars between suction and discharge. The parameters for all the equipment included must be specified by opening equipment icons and defining necessary data. If you are using any additional input streams such as steam for heating or additional feed, then those streams need to be specified as well. The flowrate, composition, temperature, and pressure of this stream must be specified.

In a simple case, as the basic column described above, there is only one input stream, the column feed stream. The input streams to the process must be specified. If you do not have any specific knowledge or requirements, it is best to use the suggested thermodynamics package.

#Pro ii simulation manual software#

Most of the software packages will suggest the thermodynamic property package that suits defined components. Next, we must define the chemical components involved in the separation. Optionally, you can also define accumulation vessel for the condensate.

#Pro ii simulation manual pro#

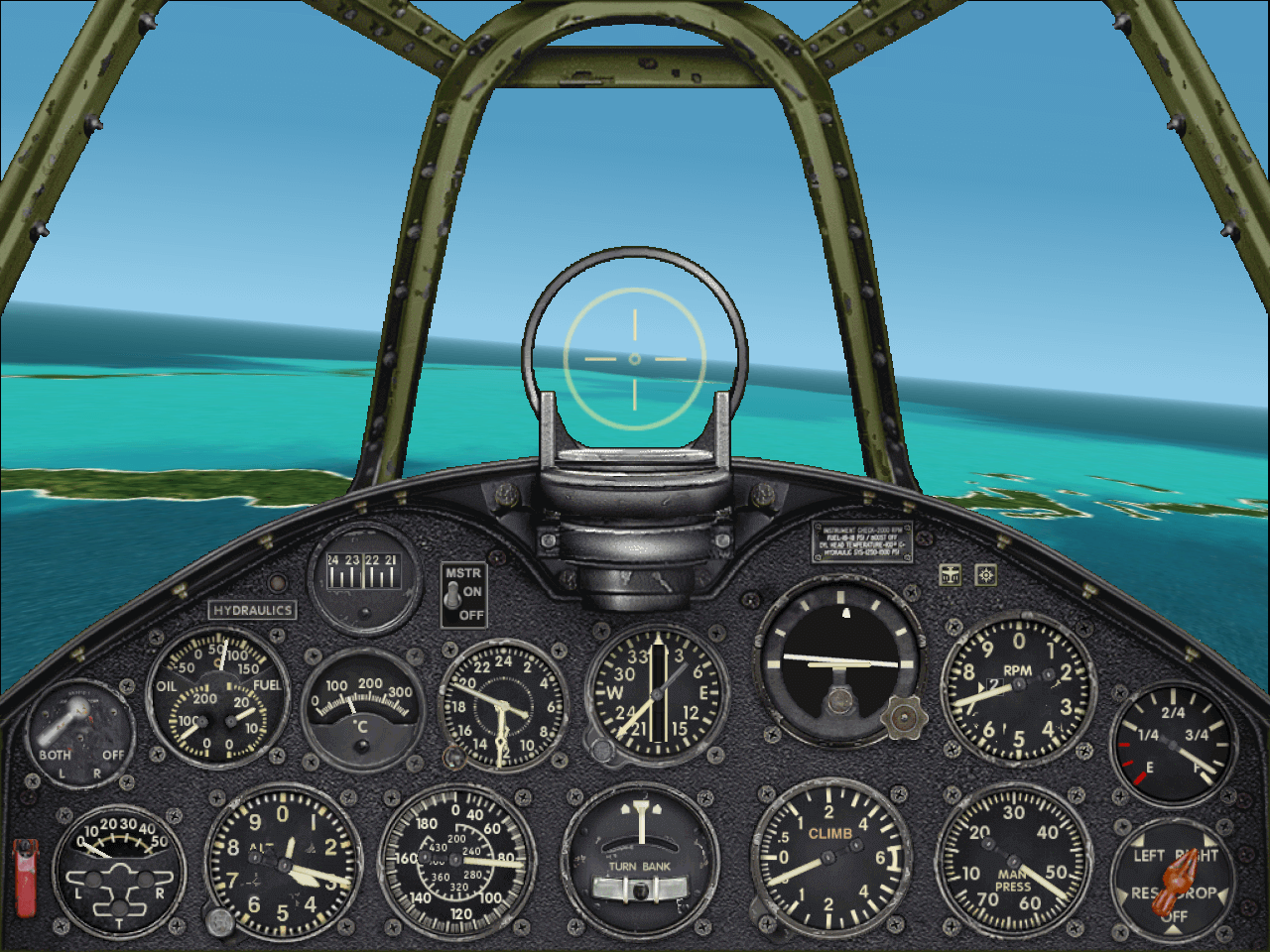

Whatever process simulator software you are using (Hysys, Aspen Plus, ChemCad, Pro II), the first step is to open a blank worksheet and add a pieces of process equipment: column, condenser, reboiler (as part of the column or separate), pumps and valves and add a streams between them. The desired compositions of the product streams are also typically known.Ī Step-by-Step Guide 1. Not all of these variables are independent, so a “degrees of freedom” analysis is useful in pinning down exactly how many independent variables can be specified to completely define the system.Ī rigorous degrees-of-freedom analysis involves counting the number of variables in the system and subtracting the number of equations that describe the system.Ī typical situation in distillation design is that the feed conditions are given: flowrate, composition, temperature, and pressure. The design of a distillation column involves many parameters: product compositions, product flowrates, operating pressure, total number of trays, feed tray location, reflux ratio, reboiler heat input, condenser heat removal, column diameter, and column height. Understanding of vapor–liquid equilibrium is essential for the analysis, design, and control of distillation columns. Distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation. The basis of distillation is phase equilibrium, specifically, vapor–liquid phase equilibrium. To help you get the results of the simulation quickly and every time - follow the easy instructions below. Sometimes, calculating a column using a process simulation package can be a time-consuming task.

#Pro ii simulation manual manual#

The utility eliminates the need for manual transfer of data between KG-TOWER and PRO/II software applications.Distillation is one of the most important operations in chemical engineering and also one of the most challenging operations for modeling and control. PRO/II to KG-TOWER® software integration.

#Pro ii simulation manual registration#

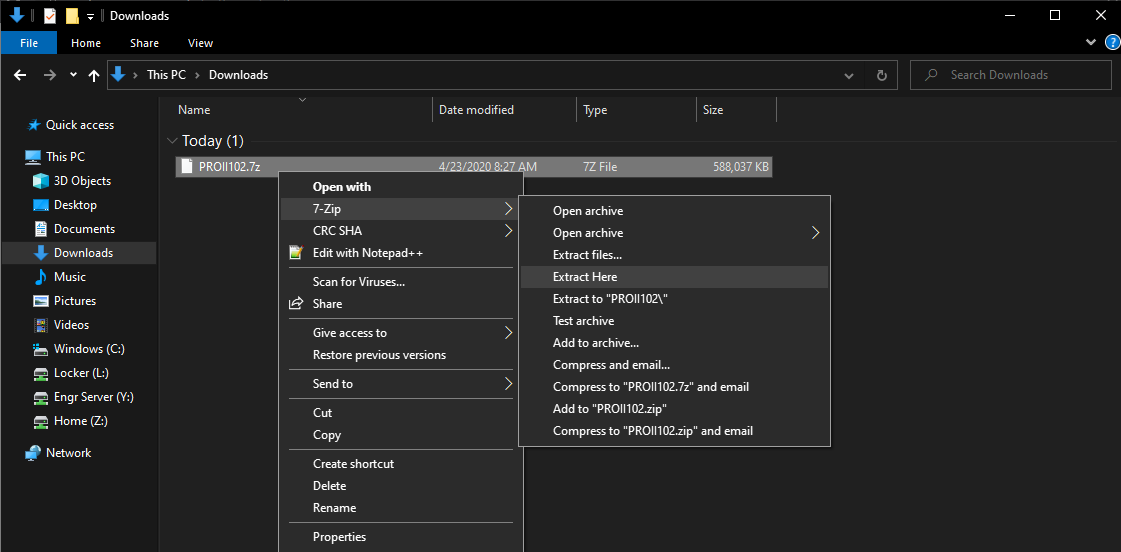

Select KG-TOWER® equipment rating program to go to the KG-TOWER software registration page. You will need to register for the KG-TOWER® software to obtain the PRO/II utility.

#Pro ii simulation manual download#

0 kommentar(er)

0 kommentar(er)